I-Ferromolybdenumi-ferroalloy ehlanganisa insimbi ne-molybdenum. Amazwe aphezulu ekukhiqizeni i-ferromolybdenum yi-China, i-United States, ne-Chile, ehlanganisa cishe u-80% wokukhiqizwa kwe-molybdenum ore emhlabeni. Ikhiqizwa ngokuncibilikisa ingxube ye-molybdenum concentrate kanye ne-iron concentrate esithandweni. I-Ferromolybdenum iyingxubevange eguquguqukayo engasetshenziswa ezinhlelweni ezahlukahlukene ezimbonini ezahlukahlukene.

Indawo enkulu kunazo zonke yokufaka isicelo se-ferromolybdenum alloys ukukhiqizwa kwama-alloys ensimbi. Ngokuya ngobubanzi bokuqukethwe kwe-molybdenum,

ama-alloys e-ferromolybdenumingasetshenziswa ukwenza amathuluzi emishini nemishini, i-hardware yezempi, amapayipi okuhluza, izingxenye ezithwala imithwalo, kanye nezinsimbi zokubhola ezijikelezayo.

Ama-alloys e-Ferromolybdenumasetshenziswa nasezimotweni, amaloli, izitimela kanye nemikhumbi. Ama-alloys e-Ferromolybdenum asetshenziswa ezinsimbi ezingagqwali nezimelana nokushisa kumafutha okwenziwa kanye nasezitshalweni zamakhemikhali, izishintshisi zokushisa, amajeneretha, izinto zokucwenga, amaphampu, amapayipi ophephela, ophephela basolwandle, amapulasitiki, neziqukathi zokugcina i-asidi.

Izinsimbi zamathuluzi ezinokuqukethwe okuphezulu kwe-molybdenum zisetshenziselwa izingxenye zemishini ezinesivinini esikhulu, izimbobo, izikulufu, ama-dies, amathuluzi abandayo, amashizolo, ama-castings asindayo, amaroli, ama-cylinder blocks, izigayo zamabhola namaroli, izindandatho zepiston, nezinsimbi ezinkulu.

Kunezindlela ezimbili zokukhiqiza i-ferromolybdenum. Enye iwukukhiqiza amabhulokhi okunciphisa i-carbon ferromolybdenum enekhabhoni ephezulu esekelwe esithandweni sikagesi, kanti enye iwukukhiqiza i-low-carbon ferromolybdenum-based ... (3) I-akhawunti yokuqeda nokushisa i-steam yengxenye enkulu yensimbi ebuyisiwe, okudingeka zincibilikiswe futhi zigaywe kabusha.

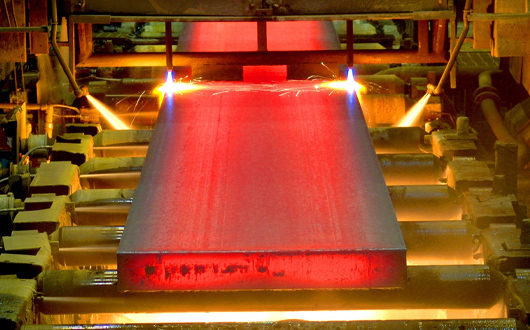

Indlela yokunciphisa ukushisa kwensimbi esithandweni somlilo (ngokuvamile eyaziwa ngokuthi indlela yokunciphisa ukushisa kwe-silicon): Lena indlela elula, eyonga kakhulu futhi esetshenziswa kakhulu ekukhiqizeni i-ferromolybdenum.

Le ndlela isebenzisa i-silicon esikhundleni se-carbon njenge-ejenti yokunciphisa i-molybdenum oxide. I-silicon yengezwa ngendlela ye-ferrosilicon. Ukushisa okukhishwe ukusabela kokunciphisa kungancibilikisa i-alloy ekhiqiziwe kanye ne-slag. Ngakho-ke, awukho umthombo wokushisa odinga ukungezwa kusukela ngaphandle ngesikhathi sokukhiqiza, futhi kulula ukufeza ukusabela okuzenzakalelayo.

Umsebenzi oyinhloko wokukhiqizwa kwe-ferromolybdenum ukuzuza izinga eliphezulu lokutholwa kwe-molybdenum.

(1) Ukugaywa kabusha kwe

i-ferromolybdenumizinhlayiya ku-slag. Ngokuvamile, i-slag ene-colloidal molybdenum ephezulu ibuyiselwa ukuncibilikiswa, futhi i-slag equkethe inani elikhulu lezinhlayiya zensimbi iyachotshozwa bese ihlanganiswa ngozibuthe futhi ibuyiselwe.

(2) Ukugaywa kabusha kwentuthu. Nomaphi lapho kunezinhlawulo ze-molybdenum, kufanele kube nemishini eqinile nesebenzayo yokususa uthuli. Uma usebenzisa izikhwama ukususa uthuli, umlotha uqukethe cishe u-15% we-molybdenum ongabanjwa.

(3) Ukuqedwa kanye ne-steam esithandweni ingxenye enkulu yensimbi ebuyisiwe, okudingeka ibuyiselwe ekuncibilikisweni nasekusetshenzisweni kabusha.

Indima ye-molybdenum ekukhiqizeni:Ukusetshenziswa okuyinhloko kwe-molybdenum ukucwenga i-alloy steel, ngoba i-molybdenum inganciphisa izinga lokushisa lensimbi lokubola kwe-eutectic, yandise izinga lokushisa lokucisha lensimbi, futhi ingalokothi ithinte ukujula kokuqina kwensimbi.

I-Molybdenum ivame ukusetshenziswa nezinye izakhi ezifana ne-chromium, i-nickel, i-vanadium, njll. ukwenza insimbi ibe nesakhiwo sekristalu esifanayo, ithuthukise amandla, ukuqina, ukumelana nokugqoka kanye namandla okuthonya ensimbi.

I-Molybdenum isetshenziswa kakhulu ekuncibilikiseni insimbi yesakhiwo, insimbi yasentwasahlobo, insimbi enensimbi, insimbi yamathuluzi, insimbi engagqwali engamelana ne-asidi, insimbi emelana nokushisa nensimbi kazibuthe. Ngaphezu kwalokho, i-molybdenum isetshenziselwa i-alloy cast iron ukunciphisa usayizi wezinhlayiyana ze-grey cast iron, ithuthukise ukusebenza kwe-grey cast iron ekushiseni okuphezulu, futhi ithuthukise ukumelana kwayo nokugqoka.

Indima ye-molybdenum kwezolimo:I-Molybdenum isetshenziswa kakhulu kwezolimo ukuze kwandiswe isivuno sezitshalo, ikakhulukazi ngoba i-molybdenum iyisici esibalulekile sokulandelela esidlala indima ebalulekile ekukhuleni kwezitshalo, ekuthuthukisweni nasekusebenzeni komzimba. Nazi ezinye zezindlela i-molybdenum esetshenziswa ngayo kwezolimo nokuthi ingasiza kanjani ekwandiseni isivuno sezitshalo:

Ukusetshenziswa komanyolo we-molybdenum: Umanyolo we-molybdenum umanyolo oqukethe i-molybdenum ongasetshenziswa emhlabathini noma isifutho se-foliar ukunikeza i-molybdenum edingwa izitshalo. Ukusetshenziswa komanyolo we-molybdenum kungathuthukisa ukusebenza kahle kokusetshenziswa kwe-nitrogen ezitshalweni, kukhuthaze ukumuncwa kwe-nitrogen nokugaywa kwe-metabolic, ngaleyo ndlela kwandise isivuno sezitshalo.

Ukwenza ngcono inhlabathi pH:I-molybdenum ihlangana kalula ibe izinhlanganisela ezingancibiliki emhlabathini one-asidi, okunciphisa ukumuncwa kanye nokusetshenziswa kwe-molybdenum yizitshalo. Ngakho-ke, ngokwenza ngcono inhlabathi i-pH ibe uhla olufanele, ukusebenza kahle kwe-molybdenum emhlabathini kungandiswa, okuzuzisa ukumuncwa kwe-molybdenum yizitshalo.

Izidingo ze-molybdenum zezitshalo ezahlukene: Izilimo ezihlukene zinezidingo ezihlukene ze-molybdenum, ngakho-ke lapho ufaka umanyolo, kuyadingeka ukuthi ufakwe ngokufanele ngokuvumelana nezidingo zezitshalo ezahlukene ukuze uqinisekise ukuthi izitshalo zingathola i-molybdenum eyanele.

Indima ye-molybdenum kumabhaktheriya alungisa i-nitrogen:I-Molybdenum ibalulekile futhi ekukhuleni nasekusebenzeni kwe-nitrogen-fixing bacterium, engaguqula i-nitrogen emoyeni ibe uhlobo olungasetshenziswa izitshalo. Ngakho-ke, ngokuhlinzeka nge-molybdenum eyanele, umsebenzi we-nitrogen-fixing bacteria ungakhuthazwa, inani le-nitrogen eligxilwe emhlabathini lingandiswa, futhi isivuno sezitshalo singandiswa.

Ngamafuphi, i-molybdenum ne-ferromolybdenum yizici ezibalulekile nezinto zokusetshenziswa empilweni yesimanje yezenhlalo.