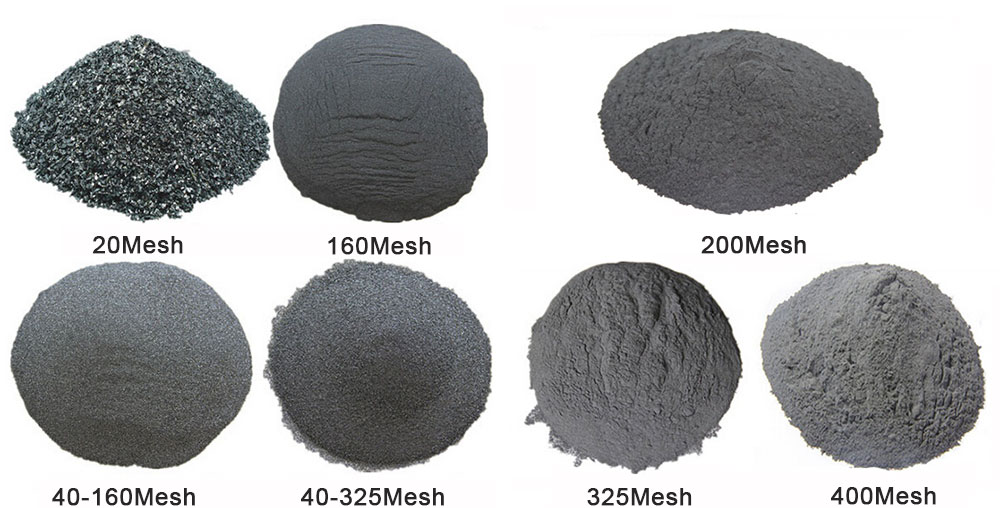

Silicon Metal Powder

Silicon metal is cleaned, selected, and ground into fine powder of 20 mesh to 600 mesh. According to the content, it can be divided into 90 metal silicon powder and 95%, 97%, 98%, 99.99% and other quality standards, and the price is low.

In the process of producing refractory materials, different specifications can be selected according to the requirements of refractory materials, thus greatly reducing the cost of refractory materials.

Silicon metal powder is typically stored in a dry, cool place to prevent oxidation and degradation of its properties.

1.Steel industry:

A large amount of silicon metal is used for smelting into ferrosilicon alloy, and it is also a reducing agent in the smelting of many kinds of metals. Silicon metal can replace aluminum in the steelmaking process, improve the efficiency of deoxidizers, purify molten steel, and improve the quality of steel.

2.Aluminum alloy:

Silicon is also a good component in aluminum alloys, and most cast aluminum alloys contain silicon.

3.Electronics Industry:

Metallic Silicon is the raw material of ultra-pure silicon in the electronics industry. Electronic devices made of semiconductor silicon have the advantages of small size, lightweight, good reliability, and long life.

4.Chemical industry:

Silicon metal is used to produce silicone rubber, silicone resin, silicone oil and etc. Silicone rubber has good elasticity that can be used to make medical supplies and gaskets. Silicone resins are used to produce insulating paints, high-temperature coatings, etc.

►Zhenan Ferroalloy is located in Anyang City,Henan Province,China.It has 20 years of production experience.High-quality ferrosilicon can be produced according to user requirements.

►Zhenan Ferroalloy have their own metallurgical experts,ferrosilicon chemical composition,particle size and packaging can be customized according to customer requirements.

►The capacity of ferrosilicon is 60000 tons per year,stable supply and timely delivery.

►Strictly quality control,accept the third party inspection SGS,BV,etc.

►Having independent import and export qualifications.

.jpg)

.jpg)