Ferro silicon 75 is a common metallurgical material with 75% silicon content, which is a common raw material used in steel making. The raw materials used to produce ferro silicon 75 are mainly coke, steel chips and quartzite, which are produced by heating and smelting in electric furnaces.

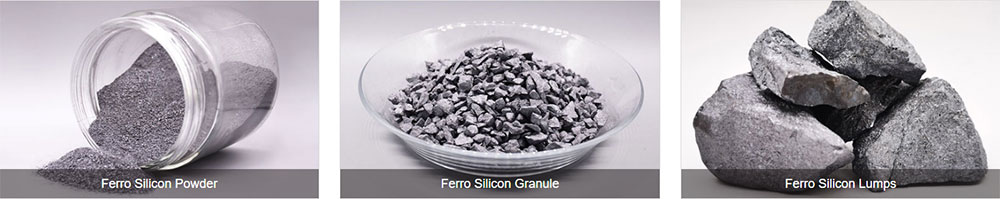

Ferro silicon is an important alloy, which can remove oxygen from the steel in iron and steel production and increase the final quality of the steel. Ferrosilicon is also the basis of pre-alloys for the manufacture such as fesimg for the modification ofmelted malleable cast irons. Ferrosilicon is a type of alloy, silver-gray, with blocky, spherical, granular and powdery shapes. In the steelmaking industry, about 3-5kg of 75% ferrosilicon is consumed to produce one ton of steel.

.jpg)

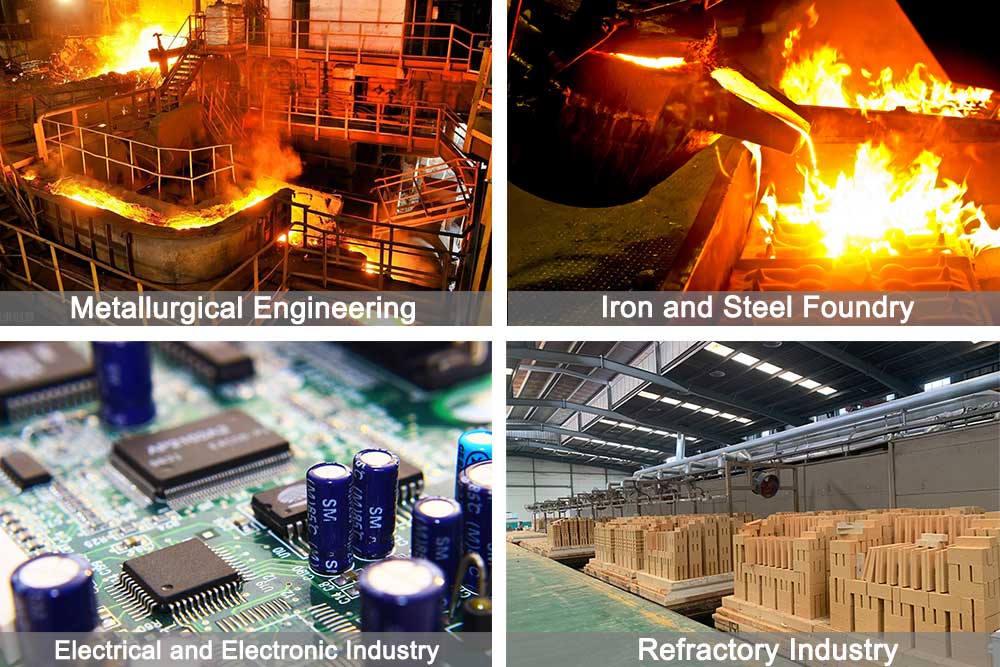

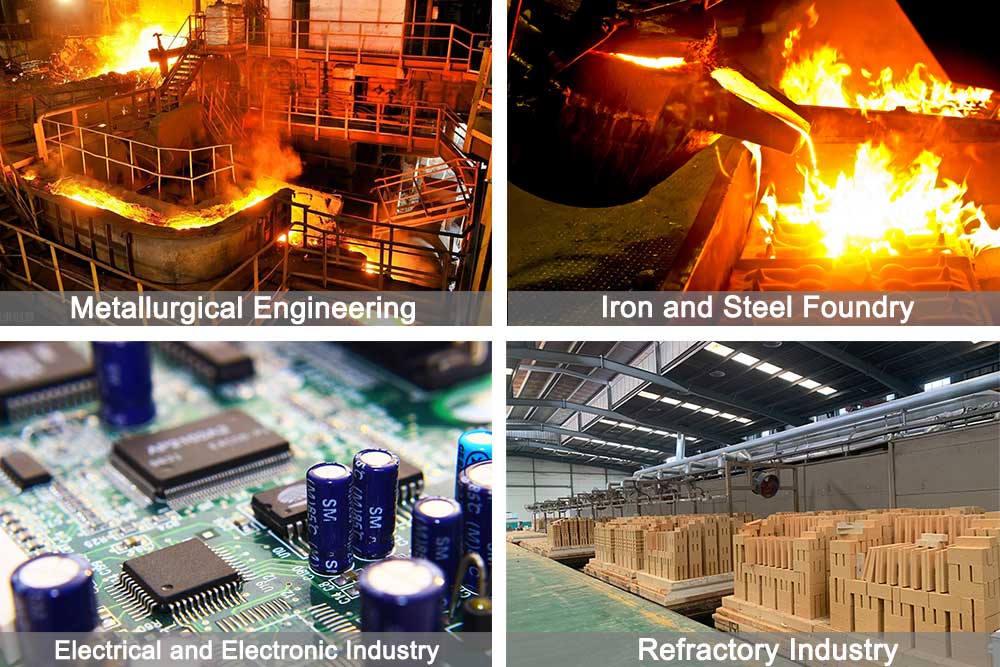

1.Ferro silicon is widely used as deoxidizer and alloy additive in steelmaking.

2.Ferro silicon powder emits a lot of heat in steel making production, and is used as a heating agent for steel ingot caps to improve the recovery rate and quality of steel ingots.

3.Ferrosilicon can be used as inoculant and nodulizer for cast iron.

4.High silicon content ferrosilicon alloy is a commonly used reducing agent in the production of low-carbon ferroalloys in the ferroalloy industry.

5.Ferrosilicon powder or atomized ferrosilicon powder can be used as coating for welding rod production.

6.Ferrosilicon can be used for high-temperature smelting of magnesium metal. 1 ton of metallic magnesium needs to consume about 1.2 tons of ferrosilicon.

1. Reducing chilling tendency significantly and relative hardness, improve machinability.

2. High anti-decline ability, prevent declining of inoculants and nodular iron.

3. Enhance the cross section uniformity and prevent the shrink tendency.

4. Steady chemical composition. Even processing granularity.

Small deviation in quality and ingredients.

5. Low melting point(approaching 1300℃). Easy for melting absorb and has little dross.

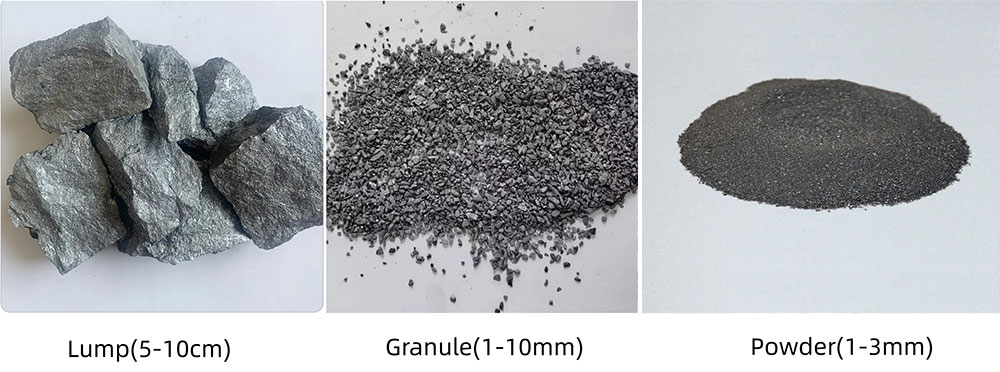

Size:0.2-0.7mm,0.7-1.0mm,1.0-3.0mm,3.0-8.0mm

The size also can be produced as the customer's demand.

High Carbon Silicon: Good substitute for ferro silicon & low cost, details>

Offgrade Silicon Slag: Very cheap deoxidizer for steelmaking, details>

Alloys Cored Wire: Accurately control the amount of alloy material added, more advanced, details>

►Zhenan Ferroalloy is located in Anyang City,Henan Province,China.It has 30 years of production experience.High-quality ferrosilicon can be produced according to user requirements.

►Zhenan Ferroalloy have their own metallurgical experts,ferrosilicon chemical composition,particle size and packaging can be customized according to customer requirements.

►The capacity of ferrosilicon is 60000 tons per year,stable supply and timely delivery.

►Strictly quality control,accept the third party inspection SGS,BV,etc.

►Having independent import and export qualifications.

.jpg)

.jpg)