Description

Ferro Alloy as a steelmaking deoxidizer, the most widely used are silicomanganese, ferromanganese and ferrosilicon. Strong deoxidizers are aluminum (aluminum iron), silicon calcium, silicon zirconium, etc. (see steel deoxidation reaction). Common varieties used as alloy additives are: ferromanganese, ferrochrome, ferrosilicon, ferrotungsten, ferromolybdenum, ferrovanadium, ferrotitanium, ferronickel, niobium (tantalum) iron, rare earth ferroalloys, ferroboron, ferrophosphorus, etc. According to the needs of steelmaking, various ferroalloys are stipulated in many grades according to the content of alloy elements or the level of carbon content, and the content of impurities is strictly limited.

Ferroalloys containing two or more alloying elements are called composite ferroalloys.The use of such ferroalloys can add deoxidizing or alloying elements at the same time, which is beneficial to the steelmaking process and can comprehensively utilize symbiotic ore resources more economically and rationally. Commonly used are: manganese silicon, silicon calcium, silicon zirconium, silicon manganese aluminum, silicon manganese calcium and rare earth ferrosilicon.

Specification

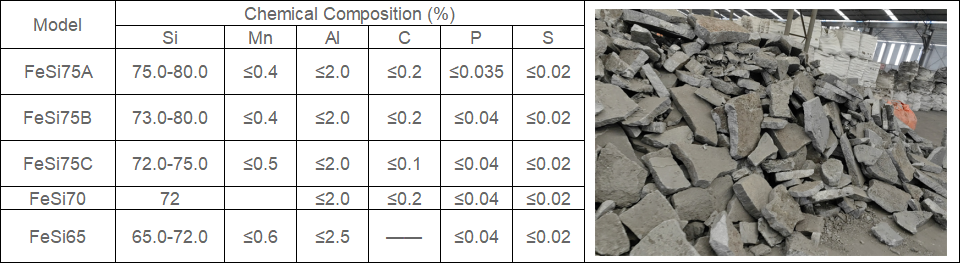

Ferro silicon

Application:

1. Used as a deoxidizer and alloying agent in the steelmaking industry.

2. Used as an inoculant and spheroidizing agent in the cast iron industry.

3. Used as a reducing agent in the production of ferroalloys.

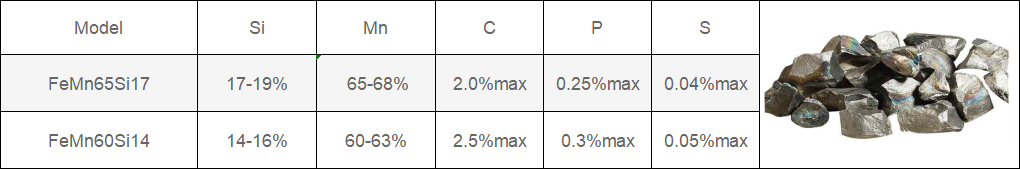

Ferro Silicon Manganese

Application:

Steelmaking has been widely used, its output growth rate is higher than the average growth rate of ferroalloys, higher than the growth rate of steel, becoming an indispensable composite deoxidizer and alloy augment in the steel industry. Manganese-silicon alloys with carbon content of less than 1.9% are also semi-finished products for the production of medium and low-carbon manganese iron and electrosilic thermal metal manganese.

Ferromolybdenum

Application:

1.Used as reducing agent in the production of ferroalloy and magnesium

2.Used as deoxidizer and alloying agent in the steelmaking industry

3.Used as inoculant and nodulizer in the cast iron industry

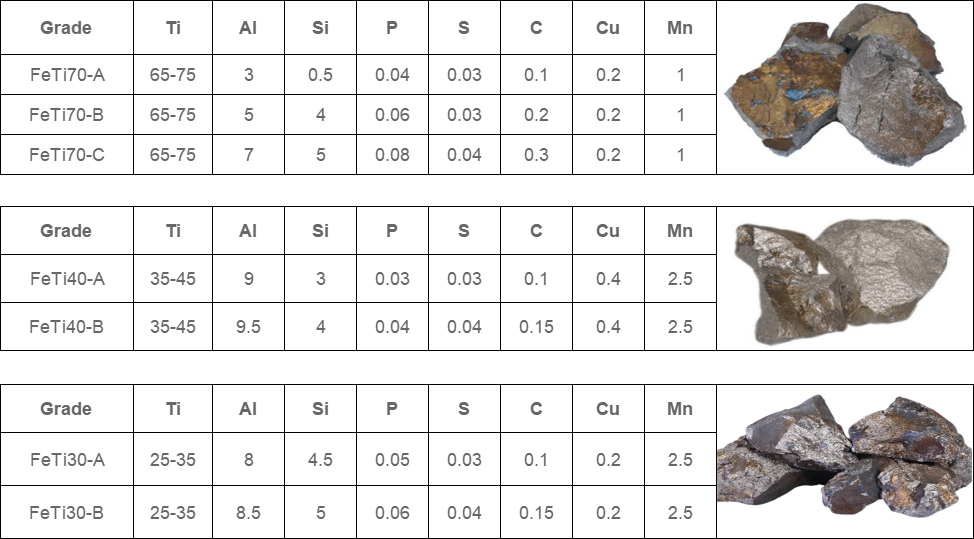

Ferrotitanium

Ferrotitanium produces quality improvements in steel and stainless steel materials, which is why it’s commonly used in steel refining, including the deoxidation, denitrification and desulfurization processes. Other uses of ferrotitanium include the production of steel for tools, military and commercial aircraft, steel and stainless steel processing units, paints, varnishes and lacquers.

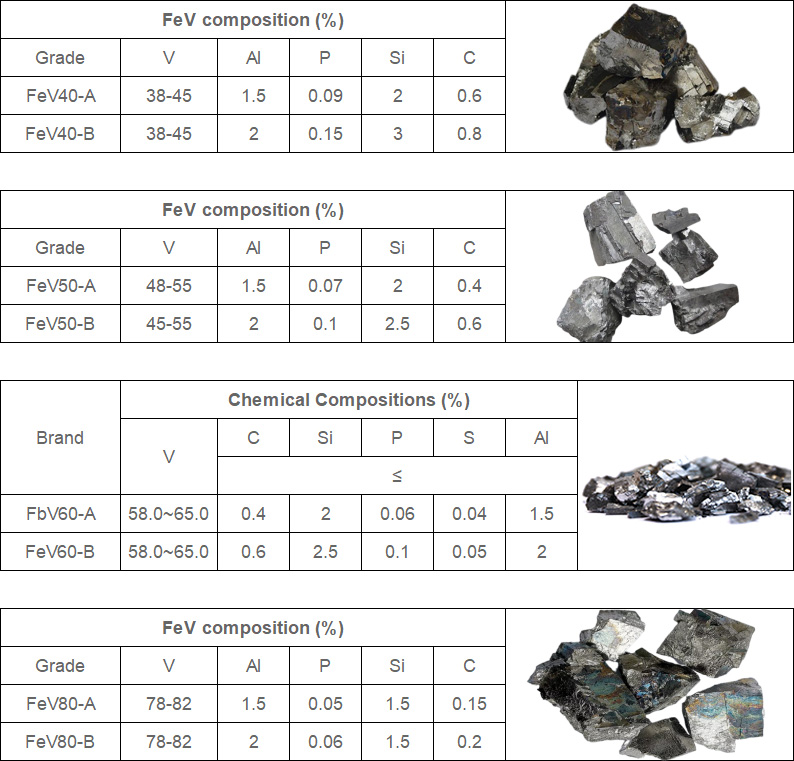

Ferro Vanadium

Ferro vanadium (FeV) is obtained either by aluminothermic reduction of a mixture of vanadium oxide and scrap iron or by reduction of a vanadium-iron mixture with coal.

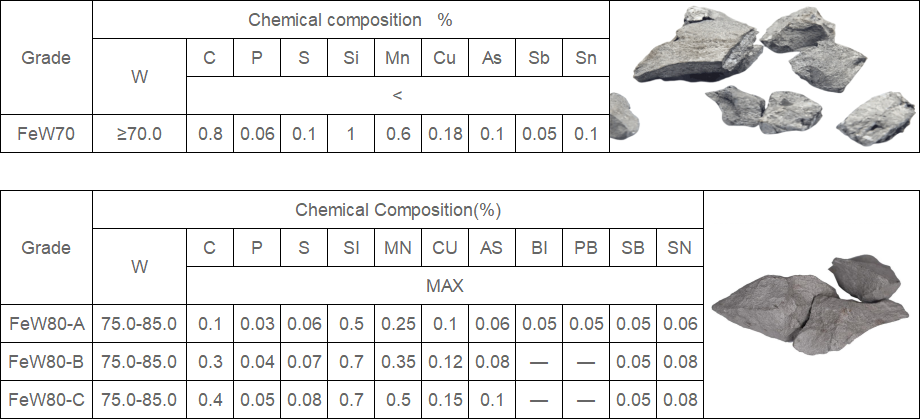

Ferro Tungsten

Ferro Tungsten is an alloy agent for steelmaking consisting mainly of tungsten and iron. It also contains manganese, silicon, carbon, phosphorus, sulfur, copper, tin and other impurities. Ferro Tungsten is prepared from wolframite by carbon reduction in an electric furnace. It is mainly used as alloying element additive for tungsten containing alloy steel (such as high-speed steel).

.jpg)

.jpg)

.png)