The cored wire is made of strip-shaped steel strip wrapped with alloy powder. According to the difference of alloy powder, it can be divided into: pure calcium cored wire, silicon calcium cored wire, silicon manganese calcium wire, silicon calcium barium wire, barium aluminum wire, aluminum calcium wire, calcium iron wire and so on.

In the melting industry, the quality of molten steel is improved by feeding the molten steel into the cored wire.

The cored wire can more effectively add smelting materials into molten steel or molten iron in the process of steelmaking or casting, effectively avoiding the reaction with air and slag, and improving the absorption rate of smelting materials.

Widely used as a deoxidizer, desulfurizer, and alloy additive, it can change the shape of molten steel inclusions and effectively improve the quality of steelmaking and casting products.

| Alloy Cored Wire |

Main components (%) |

Wire diameter (mm) |

Strip thickness (mm) |

Strip weight (g/m) |

Core powder

weight (g/m) |

Uniformity (%) |

| Silica calcium wire |

Si55Ca30 |

13 |

0.35 |

145 |

230 |

2.5-5 |

| Aluminum calcium wire |

Ca26-30AI3-24 |

13 |

0.35 |

145 |

210 |

2.5-5 |

| Calcium iron wire |

Ca28-35 |

13 |

0.35 |

145 |

240 |

2.5-5 |

| Silica calcium barium wire |

Si55Ca15Ba15 |

13 |

0.35 |

145 |

220 |

2.5-5 |

| Silica aluminum barium wire |

Si35-40Al 12-16 Ba9-15 |

13 |

0.35 |

145 |

215 |

2.5-5 |

| Silica calcium aluminum barium wire |

Si30-45Ca9-14 |

13 |

0.35 |

145 |

225 |

2.5-5 |

| Carbon cored wire |

C98s<0.5 |

13 |

0.35 |

145 |

150 |

2.5-8 |

| High magnesium wire |

Mg 28-32, RE 2-4 Ca1.5-2.5, Ba 1-3 |

13 |

0.35 |

145 |

|

2.5-5 |

| Silicon barium wire |

SI60-70 Ba4-8 |

13 |

0.35 |

145 |

230 |

2.5-5 |

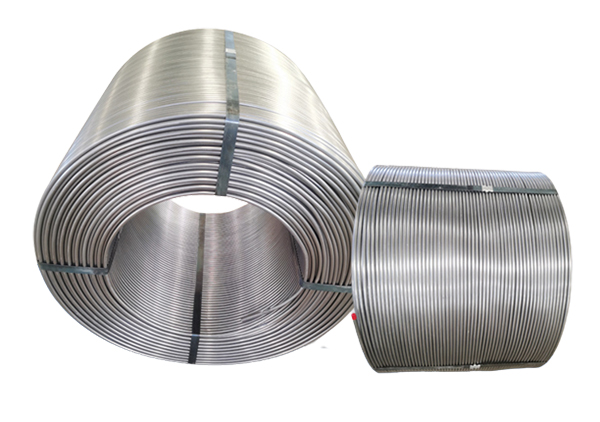

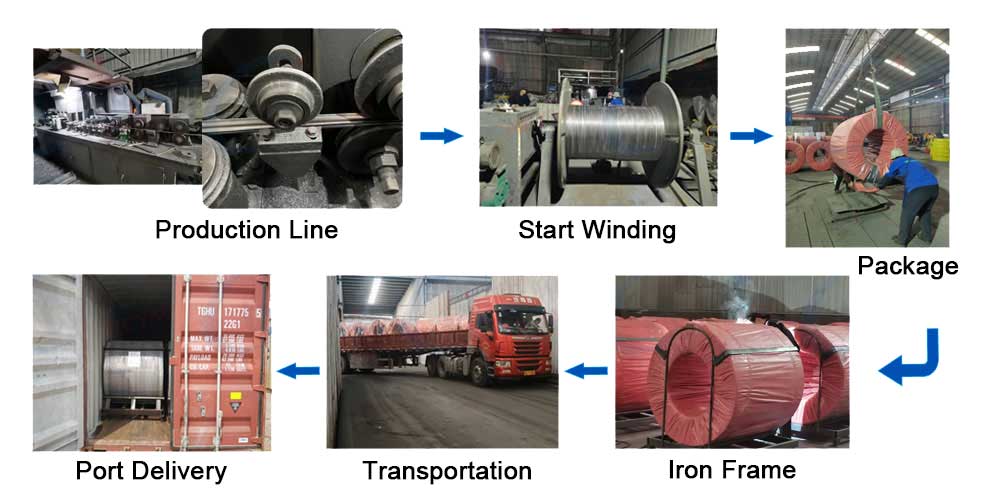

Coil Weight: 600kg±100kg, can be produced according to user requirements.

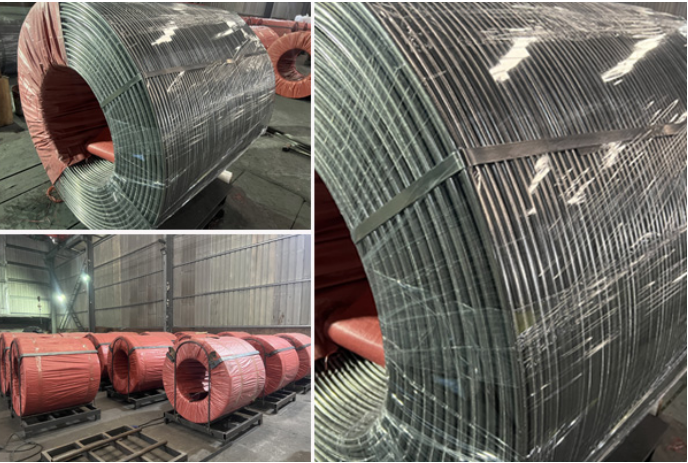

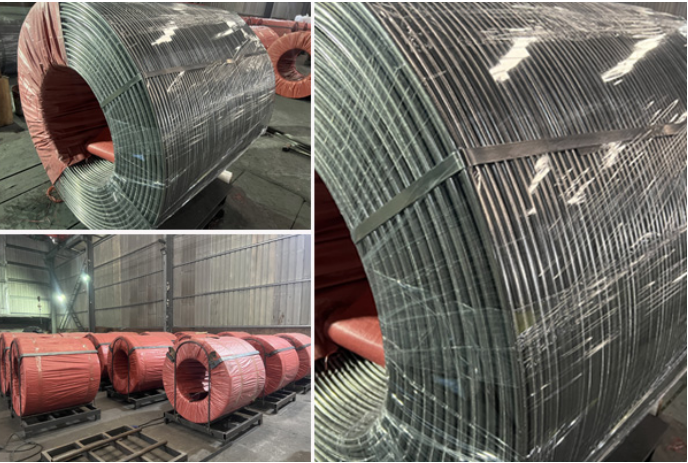

Appearance quality of core-spun wire: firm covering, no seams, no broken lines, uniform core material composition, high filling rate.

Packing: steel strap tight + waterproof plastic film + iron cover

Cable packaging: Horizontal and vertical two types of cable arrangement, divided into two types of packaging: internal tap type and external type.

Calcium iron cored wire:

Calcium iron cored wire:

Calcium iron cored wire is a method of deoxidizing molten steel in steelmaking, suitable for steelmaking enterprises. Calcium iron cored wire is a core material composed of a mixture of 30-35% metal calcium particles and iron powder. The strip steel is wrapped to make calcium iron cored wire.

Advantages of calcium-iron cored wire: It is suitable for refining molten steel, can remove residual oxygen and inclusions in molten steel, has good fluidity of molten steel, and can reduce refining costs.

High calcium cored wire:

(1) Using high-calcium cored wire for calcium treatment in the production of low-carbon and low-silicon steel can reduce the temperature drop by 2.6°C on average, reduce the silicon increase by 0.001%, shorten the wire feeding time by 1 minute, and increase the yield by 2.29 times compared with the iron-calcium wire.

(2) The feeding amount of iron-calcium wire is 3 times that of high-calcium wire. If it is converted into the same calcium content for comparison, the feeding of iron-calcium wire is 2.45 times that of high-calcium wire.

(3) High-calcium cored wire is used to process molten steel, and the level of inclusions in the steel is equivalent to that of fed iron-calcium wire, which can meet product requirements.

Calcium silicon cored wire:

The main raw material for the production of CaSi Cored Wire is Calcium Silicon alloy. The crushed calcium silicon powder is used as the core material, and the outer skin is cold-rolled steel strip. It is pressed by a professional crimping machine to make the silicon-calcium cored wire. In the process, the steel sheath needs to be tightly packed to make the core material fill evenly and without leakage.

Carbon cored wire:

Carbon cored wire is used for the purpose of increasing carbon in steelmaking, and is used for fine-tuning the carbon content of molten steel, which is beneficial to the control of carbon content in molten steel and can reduce production costs.

Carbon wire features:

1. The yield of carbon is more than 90%, and it is stable.

2. Reduce the production cost, which is lower than the cost of the currently used toner cored wire.

3. The product storage time is extended.

Alloy cored wire is suitable for deoxidation and desulfurization in steelmaking. It can improve the performance of steel, improve the plasticity, impact toughness and fluidity of molten steel. It also has the characteristics of directly entering molten steel for melting and uniform distribution tion.

►Zhenan Ferroalloy is located in Anyang City,Henan Province,China.It has 20 years of production experience.High-quality ferrosilicon can be produced according to user requirements.

►Zhenan Ferroalloy have their own metallurgical experts,ferrosilicon chemical composition,particle size and packaging can be customized according to customer requirements.

►The capacity of ferrosilicon is 60000 tons per year,stable supply and timely delivery.

►Strictly quality control,accept the third party inspection SGS,BV,etc.

►Having independent import and export qualifications.

.jpg)

Q:Are you a factory or a trading company?

A:We have factories and trading companies, factories and warehouses in Anyang, Henan Province, to provide you with the best prices and the best quality sources, and a professional international marketing team to provide you with a wide range of personalized services.

Q:What is the MOQ for trial order? Can samples be provided?

A:There is no limit to the MOQ, we can provide the best solution according to your situation. Can also provide you with samples.

Q:How long will the delivery take?

A:Once the contract is signed, our normal delivery time is about 2 weeks, but it also depends on the quantity of the order.

Q:What are your terms of delivery?

A:We accept FOB, CFR, CIF, etc. You can choose the most convenient way.

.jpg)