Titanium is not magnetic. This is because titanium has a crystal structure with no unpaired electrons, which are necessary for a material to exhibit magnetism. This means that

titanium does not interact with magnetic fields and is considered a diamagnetic material. In contrast, other metals such as iron, cobalt, and nickel are magnetic because they have unpaired electrons, which makes them attracted to magnetic fields. When these metals are subjected to a magnetic field, they become magnetized and remain that way until the field is removed.

Nonmagnetic properties of titanium

The nonmagnetic properties of

titanium make it an ideal metal for a variety of applications, including medical devices, aerospace, and chemical processing. In these applications, titanium is often chosen because it does not interfere with magnetic fields, making it a safe and reliable choice.

· Diamagnetism

Typically,

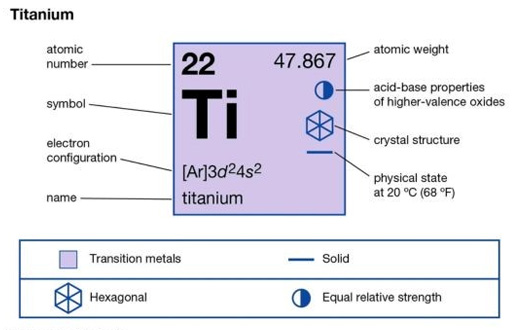

titanium has a crystal structure with no unpaired electrons.

While titanium can sometimes generate a weak magnetic field, it is usually negligible.

· Weak magnetic moment

The magnetic moments of titanium are very weak. Furthermore, they are not permanent, making titanium a magnetic material. Furthermore, even when titanium is in a magnetic field, its net magnetic moment is quite low.

· Cannot be attracted by a magnet

When you place titanium in a magnetic field, it is not attracted by the magnet. This is usually due to the lack of ferromagnetic elements or elements.

What makes titanium non-magnetic?

This is because

titanium has no unpaired electrons and a crystal structure. For a metal to exhibit magnetism, it must have a magnetic moment. For a metal to be magnetic, it must have unpaired electrons that can align their spins in the presence of a magnetic field. It is this property that makes magnets attract metals (i.e. if a metal is magnetic).

The outer electron shells of the

titanium structure allow the electrons to pair up, thus exhibiting weak magnetism.

Factors that affect the non-magnetic nature of titanium

Temperature

At room temperature,

titanium is considered non-magnetic, and its magnetic susceptibility increases at lower temperatures.

Purity

The purity of titanium affects its non-magnetic nature. This is one variable you can use to determine if titanium is pure.

For example, titanium with impurities such as ferromagnetic substances will exhibit some magnetism. In this case, you can assume that titanium is magnetic.

Alloying elements

When alloying elements are added to

titanium, it affects its non-magnetic nature. That is, alloying titanium with ferromagnetic substances will cause the material to exhibit magnetism.

In summary, while titanium alloys may exhibit some magnetism if they contain significant amounts of iron, pure titanium is nonmagnetic and can be used in a variety of applications that do not interfere with magnetic fields.

Titanium Applications

Aerospace Applications

Since the advent of the jet engine, titanium has been used in new alloys and production techniques to meet more stringent standards for high temperature performance, creep resistance, strength, and metallurgical structure.

The highest quality titanium metal alloys are obtained through triple melting, or in some cases, electron beam cold bed melting. These alloys are used in aerospace applications such as engines and fuselages.

Jet Engines

Titanium is used in critical jet engine rotating applications. In the latest technology jet engines, wide chord titanium fan blades improve efficiency while reducing noise.

Fuselage

In the fuselage structure market, innovative alloys have replaced steel and nickel alloys in landing gear and nacelle applications. These replacements allow airframe manufacturers to reduce weight and improve aircraft efficiency.

Aircraft quality steel plates and sheets are hot rolled from forged slabs. To achieve critical plate flatness, vacuum creep flattening is used. Superplastic forming/diffusion joining has led to an increased use of titanium alloy plates in new airframe designs.

Chemical Machining

Many chemical machining operations specify titanium to increase equipment life. It offers lifecycle cost advantages over copper, nickel and stainless steel, while offering initial cost advantages over materials such as high nickel alloys, tantalum and zirconium.

Petroleum

In petroleum exploration and production, the light weight and flexibility of titanium tubing make it an excellent material for deepwater production casing. In addition, titanium's immunity to seawater corrosion makes it a material of choice for topside water management systems. It is used on existing platforms in the North Sea, with more projects in the planning stages. Because titanium is virtually non-corrosive in salt water, it is also the material of choice for desalination plants around the world.

Other Industries

Titanium alloys are used in dozens of other industrial applications, such as flue gas desulfurization for pollution control, PTA plants for polyester production, pressure vessels, heat exchangers and hydraulic autoclaves. Each grade is tailored for specific operating conditions, emphasizing strength for different pressures, alloy content for different corrosive agents and ductility for different manufacturing requirements.

Emerging Applications

Pursuing, developing and supporting new uses for titanium is a priority for the titanium industry. This includes assisting companies that are developing new uses for titanium by providing a reliable supply of metal, advanced metallurgical design and expertise, and in some cases capital support.